Can urban trucks benefit from aerodynamics?

One of the most common questions we come across is whether it is ‘worth’ fitting aerodynamic kit to trucks which operate solely in urban areas. The reason people are skeptical is that these trucks carry out many short distance, low speed trips and therefore aren’t always subject to the same forces or economies of scale that larger, long-distance vehicles are.

Let’s look at the science

At Aerodyne, we’re big fans of letting the science prove or disprove this type of argument.

When a truck moves, the engine has to combat three main forces –

- Drive train friction – the loss of power in the drive train, an area in which all truck manufacturers are striving to improve efficiencies and which our aerodynamic kit cannot help;

- Tyre rolling resistance – this relates to the weight of the vehicle, the heavier it is, the more the power needed to move it;

- Aerodynamic drag – this relates to the shape of the vehicle and how it moves through the air when travelling. This force is easy to test.

Science shows that, as a vehicle doubles its speed, it needs twice the power to overcome its weight and eight times the power to overcome the aerodynamic drag. Put another way, the vehicle behaves as if it is heavier the faster it travels.

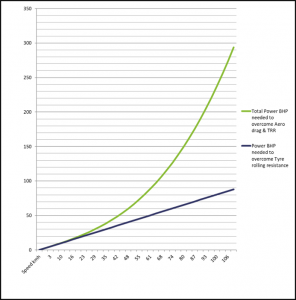

Here’s a graph for an 18-ton rigid vehicle, the type which would be used on longer, faster journeys.

The vertical axis shows the engine power required (in BHP). The horizontal axis shows the vehicle speed. In this first example below, aerodynamic drag starts to use engine power at around 18Km/h. At 50Km/h, 40 BHP (66%) is being used to overcome weight and 20 BHP (33%), aero drag. Our key interest is at the 50Km/h point.

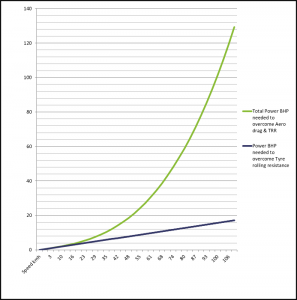

Now, look at this second graph – the same scenario but for a 3.5-ton vehicle, more like the smaller urban trucks which this article is focused on.

At 50Km/h, 8 BHP, (only 42%) is being used to overcome weight … but 11 BHP (58%) of the engine power is overcoming aero drag. This graph shows a dramatic increase in aerodynamic drag between 16 and 50 km/h, the most common speed range at which these trucks operate. This evidence leaves no room for doubt that aerodynamics are worth considering even on shorter, slower urban journeys.

In fact, the lighter the vehicle, the lower the speed required to see a benefit from aerodynamic improvements. In addition to the science, we have experience of fleets achieving a 15-20% fuel-saving benefit which results in both reduced operating costs and CO2 levels, representing wins for both the fleet’s bottom line and the environment.

| % of Power (at rear wheels) used to overcome aerodynamic drag | |||

| Weight | 50Km/h | 70Km/h | 90Km/h |

| 3.5 tons | 58% | 72% | 81% |

| 10 tons | 44% | 59% | 70% |

| 18 tons | 33% | 48% | 60% |

Aerodyne Case Study examples

Bidvest Logistics saved 11% on fuel costs

We conducted a fuel-saving trial with this large fleet operator, covering both urban and motorway routes.

Reynolds Catering achieved over 20% fuel-saving

This leading fresh fruit and veg supplier and wholesaler benefitted hugely by fitting our deflector and side-wing kit. Their 3.5tonne vehicles achieved this saving even at lower speeds.

If you’d like us to carry out an audit of your urban fleet, get on touch on sales@aerodyneuk.com or call +44 (0) 1778 442 000 and don’t forget our mantra: if we can’t save you money, we’ll tell you.