Truck Aerodynamics – What & Why?

AERODYNAMICS – Noun – “the study of the properties of moving air and the interaction between the air and solid bodies moving through it.”

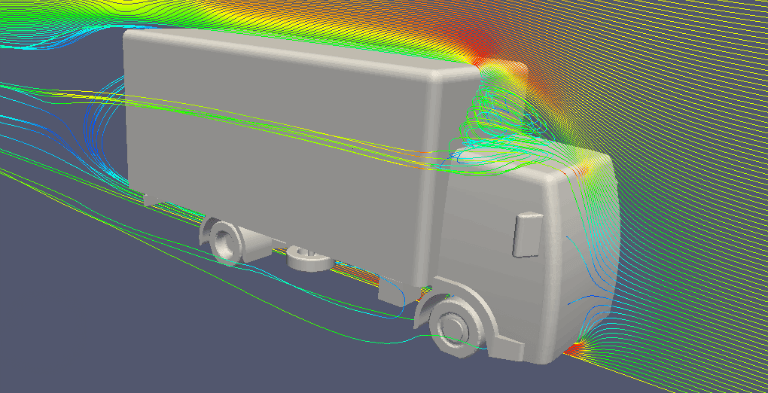

A vehicle needs power to push through the air and overcome rolling resistance. Power is fuel and fuel costs money (a lot of!). So having the most effective aerodynamics on commercial vehicles is of utmost importance in improving fuel consumption fuel and reducing pollution. If you reduce the drag factor, you improve the efficiency, you save money. Aerodynamic drag-reduction devices make the passage of air over the truck smoother and avoid wastefully stirring up or energizing the air, thus reducing the fuel consumption of the vehicle.

Minimal at low speeds, aerodynamic drag rises to colossal proportions at higher speeds. The power required to overcome it is proportional to the cube of the speed (vᵌ). For example – double the speed and you need eight times the engine power to overcome the air drag, resulting in increased fuel consumption at higher speeds.

By reducing the coefficient of drag, truck aerodynamics helps reduce the air pressure on the body or trailer front by presenting the oncoming air with a smoother-shaped vehicle. The air flowing over and around the cab is gently diverted around and over the body or trailer. Proper body-mounted aerodynamics smooths the airflow around the body’s leading edges, helping the air remain attached to the body sides thereafter, and thus reducing air drag. The easier flow-away provided for the air thus lessens fore-body pressure too.

It is also important to have the right aerodynamic devices set for the right application. A manufacturer produces a chassis cab which then goes to a body build, and the body on the back of the vehicle will have a massive effect on how the vehicle performs depending on its size, shape, weight and so on. It’ll be completely different from a box van to a flat-bed to a curtain-sider.