‘Aerodynamics for city trucks?’

I lose count of the number of times I’ve heard this comment – the view that there’s no point in fitting aerodynamics to trucks which operate only in urban areas. After all, the forces of drag that build up below 30 mph are negligible … aren’t they?

Time to think again

The science of aerodynamic drag demonstrates with crystal clarity that this assumption is simply false. Where better to look than the evidence?

When a truck moves, the engine must combat three main forces –

- Drive train friction – the loss of power in the drive train, an area in which all OEMs are striving to improve efficiencies. Let’s leave them to it.

- Tyre rolling resistance (vehicle weight and tyre performance) – the heavier the vehicle, the more the power needed to move it. High resistance tyres also increase the power demand. Funny – the very thing connecting the vehicle to the road isn’t always helpful!

- Aerodynamic drag – Our speciality! – this relates to the shape of the vehicle cutting through the air. As a vehicle accelerates and moves through our atmosphere it experiences a resistive force which is a direct consequence of the properties of the air we breathe. This resistive force is known as ‘Drag’ and increases with speed. Just stick your hand out of the window when you’re driving, you can feel the air pushing your hand backwards! In the world of aerodynamics, our aim is to reshape a vehicle such that its drag is significantly reduced – saving huge on fuel!

Now let’s turn our attention to two weights of vehicle and the amount of drag they generate at a variety of speeds.

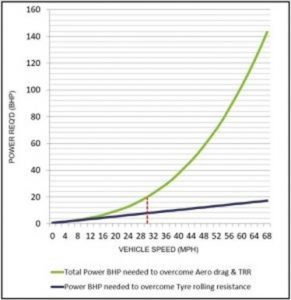

Here’s a graph for an 18-ton rigid vehicle –

As the vehicle doubles its speed, it needs 2x power to overcome its weight and 8x power to overcome aero drag.

The vertical axis shows the engine power required (in BHP). The horizontal axis shows the vehicle speed. In this first example below, aerodynamic drag starts to use engine power at around 10MPH. At 30mph, 56% (35 BHP) is being used to overcome weight and 44% (27 BHP), aero drag. Our key interest is at the 30-mph point.

Now, look at this second graph – the same scenario but for a 3.5-ton vehicle.

At 30mph, only 36% (8 BHP) is being used to overcome weight … but 64% (14 BHP) of the engine power is overcoming aero drag.

Check out the dramatic increase between 12 and 30mph.

As a rule of thumb, between 20-30mph the aero drag and rolling resistances are within close range of each other and improving either adds up to overall fuel efficiency improvements! Above 30mph, aero drag becomes the most dominant resistive force!

Low-speed aerodynamics do count

The evidence strongly supports the opportunity to influence fuel efficiency, through through aerodynamics, between 20-30mph. The lighter the vehicle, the lower the speed required to see a benefit from aerodynamic improvements. Every company operating 3.5-ton trucks in urban areas should ensure their aerodynamics are up to scratch. We know of fleets achieving over 20% fuel-saving benefit – reducing operating costs and Co2 levels. This is the perfect win-win. A win for the bottom line and a win for the environment!

Reynolds Catering achieved over 20% fuel-saving with the below deflector and side-wing kit.

|

% of Power (at rear wheels) used to overcome aerodynamic drag |

|||

|

Weight |

30mph | 45mph | 60mph |

|

3.5 tons |

57% | 74% |

84% |

|

10 tons |

40% | 59% | 73% |

| 18 tons | 28% | 46% |

61% |